-

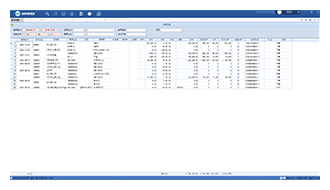

Standard Information

Corporate Basic Companies Management Department Management Item Management BOM Management Unit Price Management Exchange Rate Management

-

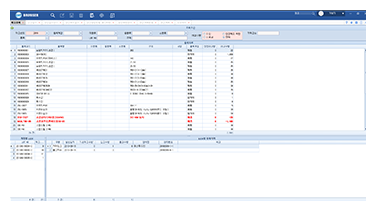

Business Management

Order processing Shipping Process Sales processing Revenue Status Factory Status Order Status Sales Status Purchase E-TAX

-

Production Management

Production plan Work order Work diary Actual production Production history Operation standard Barcode output Facility history management Monitoring actual production compared to production plan Monitoring facility operation status

-

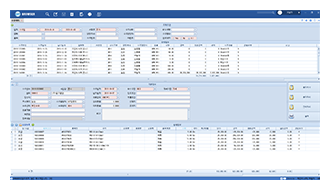

Logistics Management

Material Orders Material Input Direct Input Inventory inquiry Purchase E-TAX

-

Quality

ManagementLoT Traceback LoT Tracking Inspection Standard Nonconformity Management Process Inspection Quality Inspection Final Inspection Inquiries about Defect X Bar_R Chart SPC Tracking Management Short-term Process Capacity Status Inspection Results Marking Management Instrument Management

-

Business Management

Corporate Basic Companies Management Department Management Item Management BOM Management Unit Price Management Exchange Rate Management

Features

-

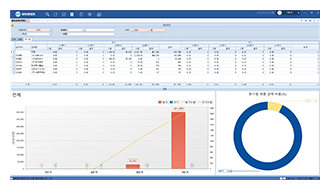

1Real-time management of manufacturing status

It effectively manages overall manufacturing collecting from the information on manufacturing, processing, product quality,and facilities.

It collects manufacturing information from in-house developed IIoT devices, barcode readers.

-

2Connecting with other systems by the integrated design of ERP, SCM, POP

Low cost and high-efficiency system by the integrated design of various systems applied to production sites

-

3Customer-specific design with modular functionality

We provide customized design and reflect company-specific requirements through on-site verification and a client consultationfrom the beginning of program development.

-

4Convenient and Easy by graphic screen

-

5Minimize expenses for upgrade and maintenance based on cloud