Application plan

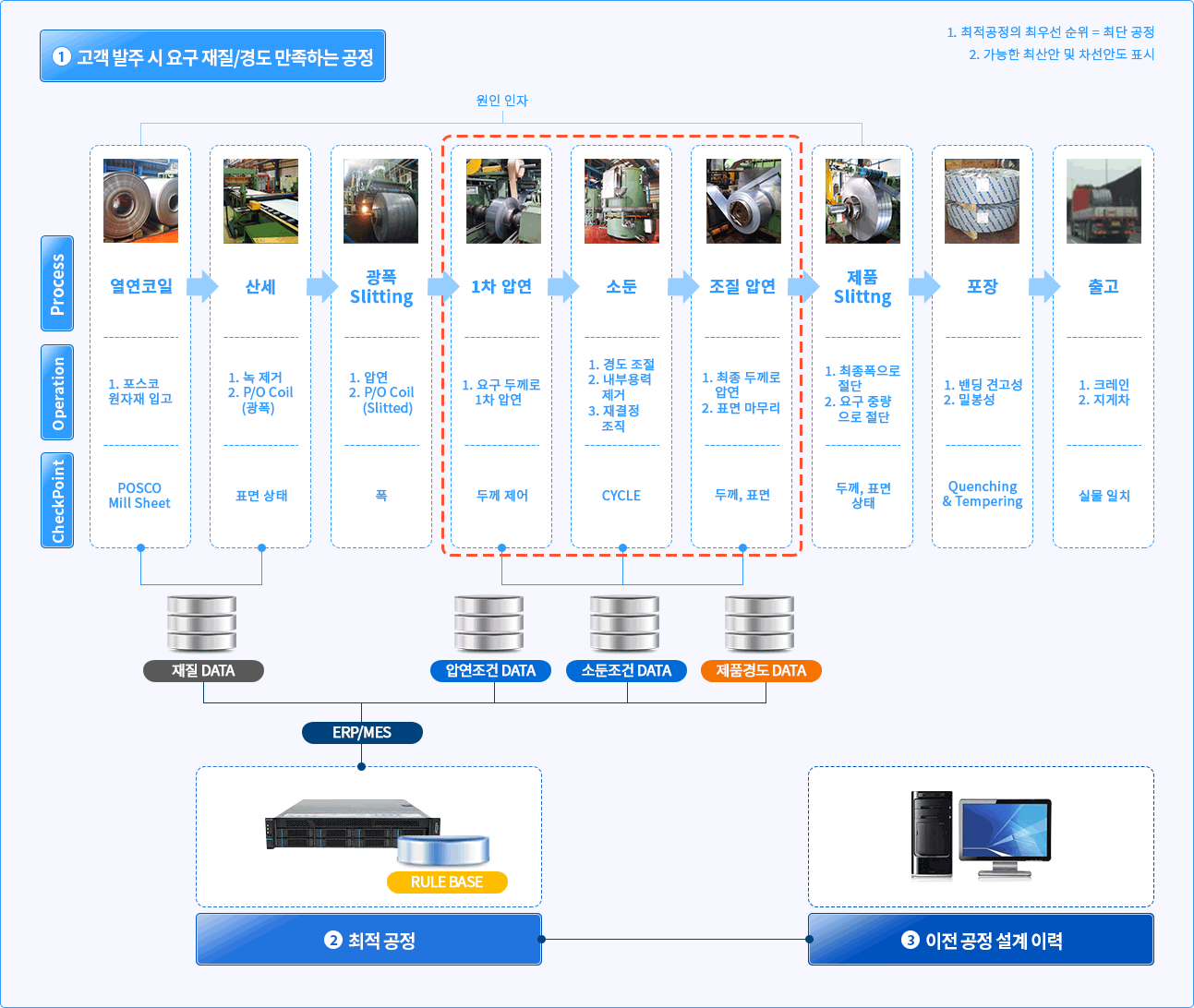

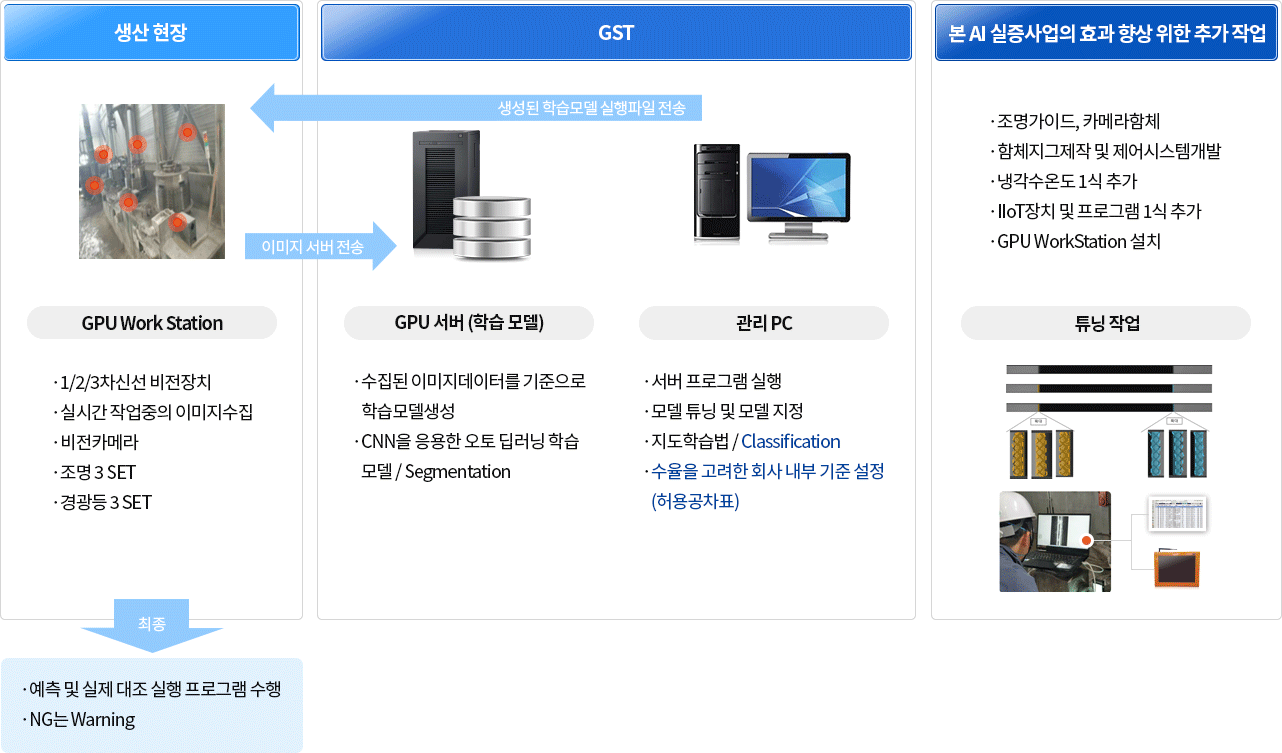

- Aiming to create more accurate process designs through AI-based big data analysis to reduce the possibility of failure and standardize optimal process designs.

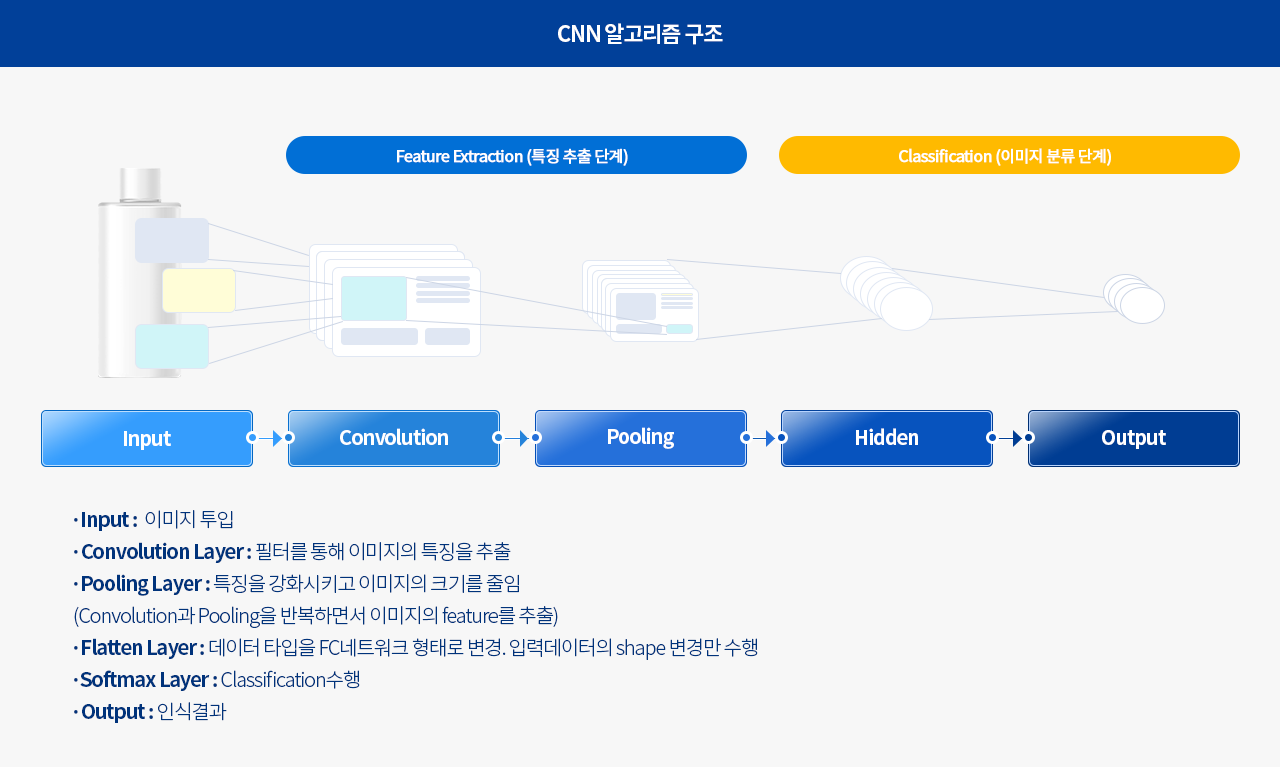

- To derive a specified result value (hardness), find the X factor factor (pressure rate, annealing condition) that affects this result value and apply it to the process design

- Based on 10 years of manufacturing data, the AI solution model is trained to find the rolling rate and annealing conditions, and then the accuracy is tested by adding raw data and comparing them.